Excel NanoSeal - Water Repellent Nano Coating

Product Description

EXCEL Nanoseal is a water repellent nano coating with 45% to 50% active nano particles. The unique superior formulation based on metal oxides, used for imparting a colorless water repellent surface finish to porous mineral / construction material / stone surfaces without significantly reducing water vapor permeability. EXCEL NanoSeal forms an excellent weather coat for all types of cement and stone surfaces. It provides water repellence and leak proof coating within 8 hours of application. The water repellence further improves over 48 hours after application.

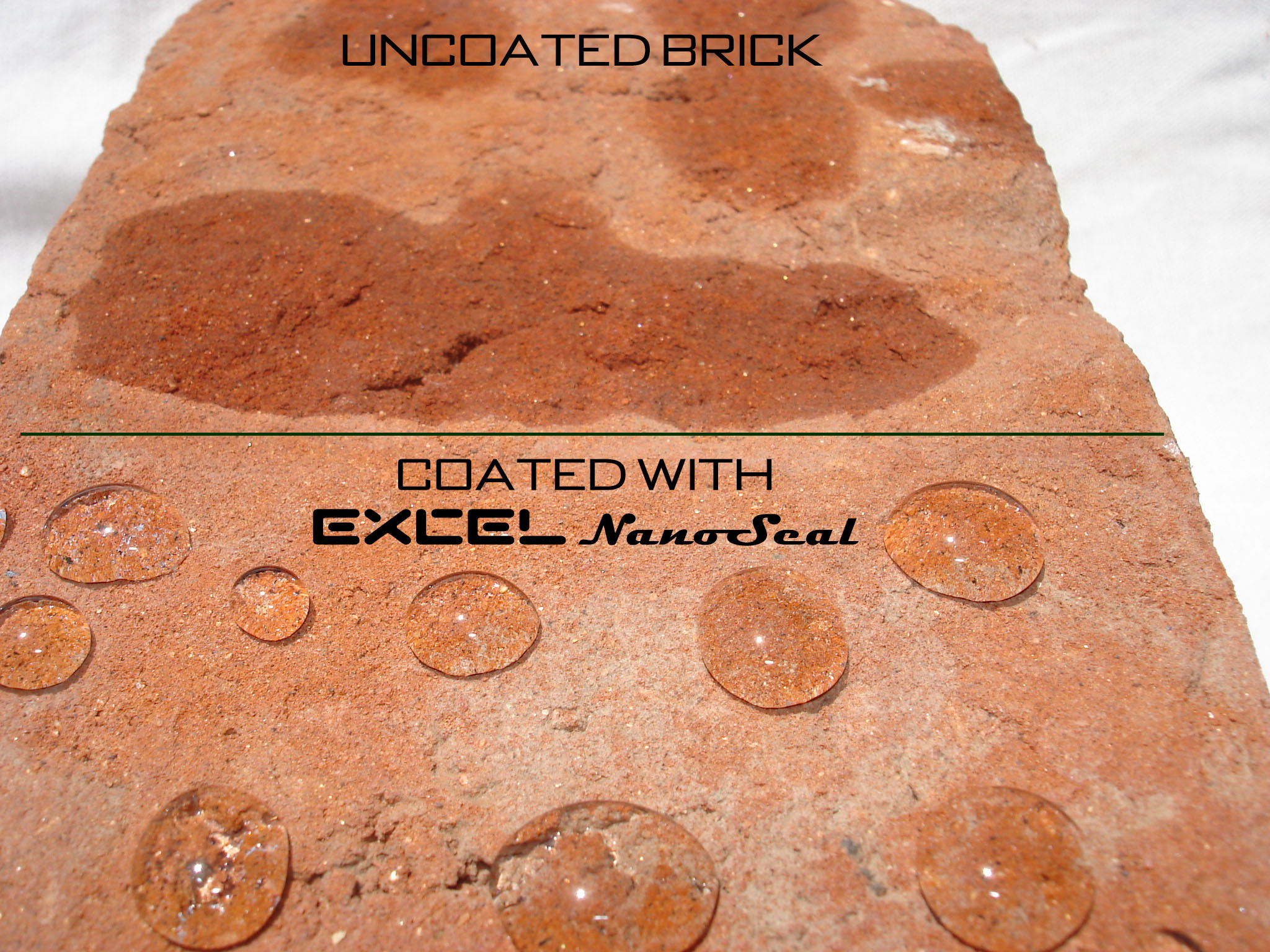

EXCEL NanoSeal by its name indicates a Super Hydrophobic, water repellent nano coating. Unlike various film of coating, EXCEL NanoSeal does not seal the pores at the surface of concrete. Instead, it penetrates into the pores and forms a very thin (nano) layer on the pore walls. These pores no longer will be wetted by water and the capillary uptake of water is prevented upto 90%.

On the surface treated with EXCEL NanoSeal, the drop of water is repelled and stands in the form of bead and does not penetrate inside. The size of EXCEL NanoSeal is 4 – 6 nm (0.005 micron) Whereas the pores on the mineral surface may vary from 5 – 200 nm. When the building materials come into contact with water, they absorb an amount of water which depends upon the porosity, resulting in penetration of water through the wall, cracks caused by swelling and shrinkage, destruction of concrete caused by corrosion of reinforced steel, lime leaching, chemical corrosion, binder transformation, etc.,

Conventional water repellents give only a short-term protection by forming a surface film. Long term protection is possible only by Nano sized water repellent, which penetrates up to 4-5mm into the surface providing capillary coating.

An unprotected building can absorb over 1 liter of water per sq. ft in 6 hours. A concrete block can absorb 2 liter of water. The rain water absorption causes multiple damages to the buildings such as penetration of water through the walls, cracks caused by swelling & shrinkage, destruction of concrete by corrosion of reinforced steel, lime leaching, chemical corrosion, binder transformation, etc.

Properties of Excel NanoSeal - Water Repellent Nano Coating

-

Water based. No solvents used. Easy application methods.

-

Waterproof and damp proof coating for superior protection.

-

Resistant against fungus, molds, mildew and leaching. Prevents ageing, scaling and salt burst.

-

Prevents structural damage. Prevents electrical shocks due to wet leaking roofs.

-

Helps in reducing spalling due to freeze-thaw efflorescence. Easiest way to repair and protect already leaking and old buildings.

-

Minimizes/stops water absorption into/by the substrate.

-

Excellent surface penetration offers excellent protection to the porous surfaces.

-

Prevents corrosion of reinforced steel used in construction. Enhances life of buildings.

Features

EXCEL NanoSeal reacts with the atmospheric moisture, thereby generating active resin while liberating moisture.

EXCEL NanoSeal should be diluted 1:12 (parts by weight) with potable water.

The active nano ingredient gives excellent water repellency to the substrate without clogging the pores or capillaries and the substrate retains a very high degree of vapor permeability.

1 kg of EXCEL NanoSeal is to be diluted in 10 to 12 lts of soft water and can cover (approx) 250 to 300 Sq.ft.

EXCEL NanoSeal Can be added as a admixture to the cement plaster.

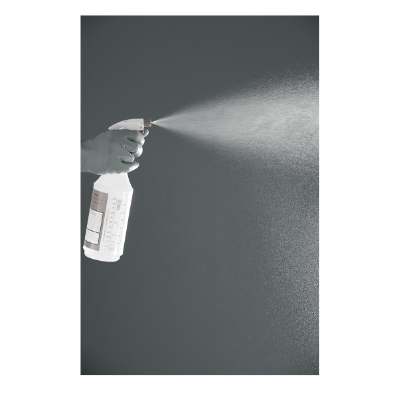

The substrate should be air dry and absorbent. The diluted solution should be liberally applied one or two coats, depending upon porosity of substrate material.

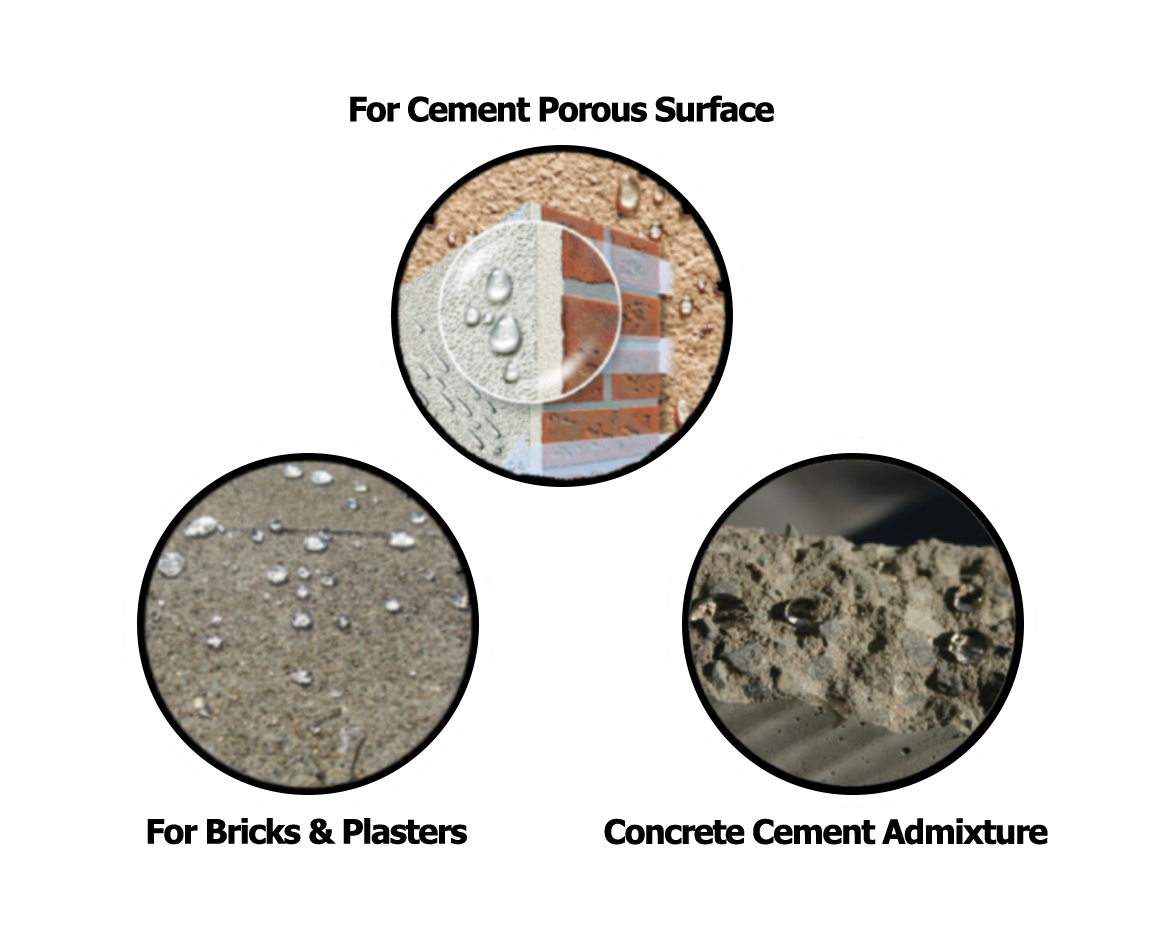

Applications

On Existing Surface

1Kg of EXCEL NanoSeal is to be diluted in 10 to 12 its of soft water and can cover (approx) 250 to 300 Sq ft.

Admixture For Cement

EXCEL NanoSeal Can be added as a admixture to the cement plaster. 300 to 500 grams of EXCEL NanoSeal to the added to every 50 kg of Cement.

Application Procedure

-

Surface Preparation

Scrub clean the surface to remove fungus and loose particles. Allow the surface to dry. Maintain the surface to be coated with EXCEL NanoSeal as dry as possible to enable maximum absorption of liquid.

-

Substrate Priming

No priming required.

-

Application

Mix 1 kg of NanoSeal Concentrate with 12 litres of water and pour it and spread it on the horizontal surface. Allow the surface to absorb for few minutes and spread the excess liquid to the next area. In case of vertical surface, apply using brush. Brush the surface from bottom up. Keep brushing the surface with the liquid until saturation. Allow the surface to dry completely approximately 48 hours to make it complete dry.

All the forms of damage can be prevented can be prevented or kept at bay for longer by means of creating EXCEL NanoSeal coated water repellent zone, which considerably stops uptake of water to keep the masonry surface dry.

-

Curing

Allow the surface to dry at least for 24 hours. Take precaution that no water falls over the surface for 48 hours. Low temperature and high humidity will slow down the curing process. In case of expected rains, do not apply EXCEL NanoSeal.

Advantages of EXCEL NanoSeal

Minimizes/stops water absorption into the substrate up to 90%.

EXCEL NanoSeal application will last for 10+ years without losing its properties.

Helps in reducing spalling due to freeze-thaw efflorescence.

Easiest way to repair and protect already leaking and old buildings.

Prevent aging, scaling and salt burst.

Water based. No solvent used.

Easy application methods.

Prevents structural damage.

Completely transparent coating.

Resistant against fungus, mold & mildew.

Excellent surface penetration offers excellent protection to the porous surfaces.

Prevent electrical shock due to wet leaking roofs.

Prevents corrosion of reinforced steel used in construction.

Enhances life of buildings.